Golden Goals: Keep Your Oils Looking Their Best!

Colour is an important quality parameter of edible oil, both in the refining process and in the marketplace. The edible oil industry often analyzes the oil colour, either qualitatively or quantitatively, during the process to maintain a consistent quality. Oil appearance might be an indicator of a problem having occurred during blending, storage, crushing, extraction and the refining process. Each oil has its own characteristics colour, primarily due to the presence of carotenoids and/or chlorophyll pigments. In addition, changes in colour may be indicative of problems in the production process, contamination, degradation or the oxidation of the materials and products. The manufacturers and producers can then carry out the necessary actions in response to the change of colour in the materials and products. Hence, it is important to have a systematic colour measurement method, technique, procedure, colour scales, oil temperature, cell path length, human factor and equipment to ensure the colour is appropriately described.

Why is it important to measure colour in edible oils?

- The colour of edible oils indicates their purity and quality, helping to identify the presence of impurities or poor refinement.

- It helps detect oxidation and degradation, as changes in colour can signal spoilage or aging of the oil.

- Colour measurements are used not only to define aesthetic qualities but also to optimize production processes like bleaching, deodorizing, and so on.

- Measuring colour ensures consistency, maintaining a uniform appearance across different production batches.

- The colour of the oil also affects consumer perception, as a clear and appealing colour enhances market acceptance.

Understanding the Standards for measuring colour of edible oils:

In a global marketplace, where oils are traded across borders and processed in different geographies, standardised methods eliminate subjectivity. They help labs, producers, and exporters speak the same language when it comes to colour—no matter the region.

Adhering to the right colour measurement standard isn’t just about compliance—it’s about building consistency, trust, and market readiness. Whether you're refining oils for domestic consumption or exporting to international markets, standards like AOCS, ISO, and BIS provide the structure for reliable colour.

evaluation.

For more insights on the Standards for Edible Oils colour measurement!

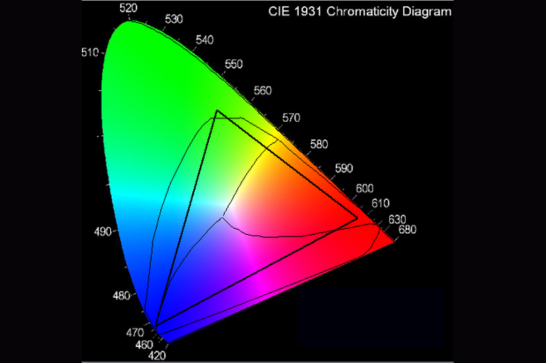

Understanding the Scales:

When it comes to colour analysis in edible oils, using the correct scale and method is critical to ensuring product consistency, compliance, and quality control. Among the various scales, the Lovibond® RYBN Colour Scale remains the most widely trusted across the industry.

Other commonly referenced scales include the Gardner Colour Scale, the AOCS-Tintometer® Scale, and the AF960 method, each with its own application and limitations. However, it's important to understand that not all methods produce comparable results.

Learn more about the Edible Oil Colour Scales!

Understanding the Lovibond® RYBN Colour Scale:

The RYBN scale is used to quantify colour using a combination of Red (R), Yellow (Y), Blue (B), and Neutral (N) glasses. It’s primarily used to assess the colour of oils, fats, chemicals, and transparent liquids by visually matching samples against calibrated glass standards in a comparator. This scale is used to measure samples which are absolutely clear, transparent and free from turbidity.

Range: 0 – 70 Red, 0-70 Yellow, 0 – 40 Blue, 0-3 Neutral

Exlpore the Lovibond® RYBN Colour Scale!

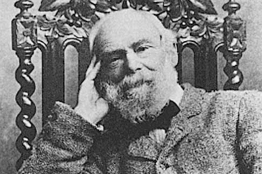

The Story Behind the Lovibond® RYBN Colour Scale:

Once upon a time in the 19th century, a brewer named Joseph Lovibond was driven by one mission: to ensure his beer always looked the same, sip after sip. He believed that consistent colour meant consistent quality but soon realised that samples of beer or chemicals changed colour with age—making them unreliable as a reference.

His breakthrough came when he noticed the unchanging beauty of coloured cathedral glass, which retained its hue over centuries. Inspired, he developed a permanent colour reference using precisely tinted glass filters—and the Lovibond® Colour Scale was born.

Want to know the journey behind the Lovibond® RYBN Colour Scale

Having trouble in measuring colour? Try these tips!

- Ensure that all oil samples are clear and free from bubbles, turbidity, or particulate matter.

- Use clean, appropriate glass cells/cuvettes free of oil marks.

- Ensure the instrument is well-maintained and routinely serviced.

- Heat samples to 10 °C above the cloud point if not liquid at room temperature.

- Record the analysis details like path length, sample temperature, sample ID, date and time, and operator.

- Ensure you adhere to the compliant standards (national/international) and use appropriate colour scales.

- Follow the specified method based on the visual or digital standard.

- If you're using visual standards, at least two or three operators should take the readings. Operators should have their colour vision tested every five years.

To support our customers, we've compiled a comprehensive guide featuring step-by-step methods for accurate and consistent oil colour analysis.

Handbook of Methods for Edible Oils and Fats:

At Lovibond®, we've been measuring colour in edible oils longer than anyone else in the industry. Over the years, we've developed reliable visual and automatic colour measurement systems that align with established standards.

Download your copy now!

Click the instrument that you're using below to take your measurements from good to great!

Even the best instruments need the right practices. Knowing how your instrument operates is just as important as using it.

Boost your colour quality control with our measurement solutions!

Contact us today!

Whether you're refining raw materials or assessing finished goods, accurate edible oil colour analysis is essential for maintaining

the highest industry standards.

FAQ's

Does Temperature affect oil colour?

Yes, temperature can affect the colour measurement of edible oil. When the oil is heated, it can undergo chemical changes such as oxidation or breakdown, which may cause it to darken or change in colour. These changes can lead to shifts in measured colour values, indicating a possible decline in the oil’s quality or stability. Temperature can also affect the oil's viscosity and transparency, which may further influence the accuracy of colour measurement.

Can the cell path length affect the results?

Yes, the cell path length can affect the results of colour measurement. It should be chosen based on the colour intensity of the oil. Generally, a shorter path length is recommended for darker oils to avoid overly high absorbance, while a longer path length is better suited for lighter oils to ensure accurate detection of colour differences.

Why are Lovibond® cells preferred?

When do you report colour as Y+ 5R?

Colour is a powerful tool for brand recognition. Consistent colour across products can strengthen brand identity.

Can you find digital instruments for colour measurement in Edible Oils and Fats?

Yes! We offer a variety of instruments for digital colour measurement in both transmission and reflectance modes, depending on your needs. Feel free to contact us for more information!

What are the basic sample requirements for colour measurement in edible oils?

For accurate colour measurement in edible oils, the sample should be clear and transparent, without any cloudiness or particles. It’s also important to make sure there are no air bubbles in the sample when placing it in the chamber, as this can affect the accuracy of the results.

In which phase of processing do we need to measure the colour of the oil?

Colour measurement in edible oils is commonly performed during refining processes such as bleaching, filtration, deodorization, and storage.

Service Request

Service Request  Sales Enquiry

Sales Enquiry  Customer Reviews

Customer Reviews