Weaving a Perfect Palette: How Lovibond® Colour Measurement Transforms Your Production

In today's global marketplace, colour is far more than just an aesthetic choice; it's a critical indicator of quality, consistency, and brand identity. From the vibrant threads of a textile to the sleek finish of a plastic product or the protective layer of a coating, achieving and maintaining precise colour is paramount. This is where Lovibond® colour measurement solutions step in, offering unparalleled accuracy and reliability for industries where colour consistency is non-negotiable.

Why does colour measurement matter so profoundly in the Textiles, Plastics, and Coatings industries?

Imagine a car with mismatched door panels, or a batch of plastic toys with varying shades. Inconsistent colour signals poor quality and can lead to product rejection, costly reworks, and wasted materials. Precise colour measurement ensures every batch, every product, every component meets exacting colour specifications, maintaining uniformity across production lines and supply chains. Brands often provide precise colour standards that manufacturers must adhere to. Objective colour data, rather than subjective visual assessment, allows for clear communication and verifiable compliance with these specifications, preventing disputes and ensuring customer satisfaction.

International Standards Guiding Colour Measurement

To ensure global consistency and comparability, various international standards govern colour measurement in textiles, plastics, and coatings. Adherence to these standards is crucial for quality assurance and trade. Some key standards include:

ASTM Standards: The American Society for Testing and Materials (ASTM) provides numerous standards for colour measurement in various materials. Examples include:

- ASTM D1544: A standard test method for measuring the colour of transparent liquids using the Gardner colour scale. This method involves comparing the colour of a liquid sample to a series of numbered glass standards. The standard applies to various materials, including drying oils, varnishes, fatty acids, and resin solutions.

- ASTM D2244: Standard Practice for Calculation of Colour Tolerances and Colour Differences from Instrumentally Measured Colour Coordinates: This standard describes the procedure for calculating colour differences and tolerances using instrumentally measured colour coordinates. It is used to evaluate the colour match or difference between textile samples and a standard.

- ASTM D1729: Standard Practice for Visual Appraisal of Colours and Colour Differences of Diffusely-Illuminated Opaque Materials.

- ASTM E1347: Standard Test Method for Colour and Colour-Difference Measurement by Tristimulus (CIE Lab* or Hunter Lab) Colorimetry.

- ASTM D1003: Standard Test Method for Haze and Luminous Transmittance of Transparent Plastics.

- ASTM D523: Standard Test Method for Specular Gloss.

ISO Standards: The International Organization for Standardization (ISO) also publishes relevant standards, such as:

- ISO 105-A02: Textiles – Tests for colour fastness – Part A02: Grey scale for assessing change in colour.

- ISO 7724 (Parts 1-3): Standards for paints and varnishes, determining colour and colour difference.

Industry-Specific Scales: Beyond universal colour spaces, certain industries utilize specialized colour scales. For instance, in some applications, the Lovibond® scale itself remains a recognized standard for specific product types (e.g., in edible oils, where Lovibond® has a rich history).

Choosing the Right Colour Scale: A Strategic Decision

Selecting the appropriate colour scale is fundamental to accurate and meaningful colour measurement. The choice depends heavily on the material, application, and the specific information needed.

Common Colour Scales and Their Applications:

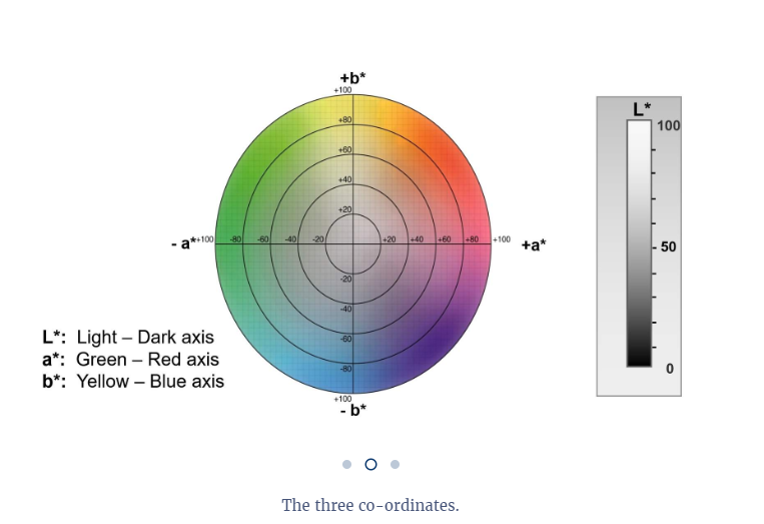

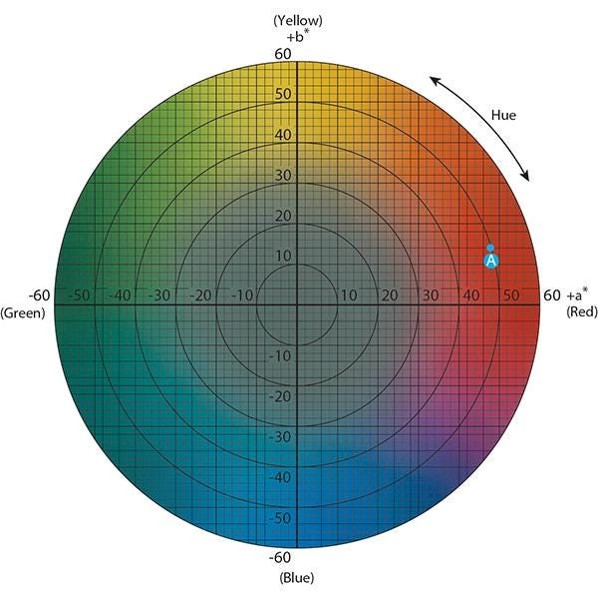

CIE Colour Spaces (e.g., CIE L*a*b*): The International Commission on Illumination (CIE) developed standardized colour spaces like L*a*b* (L∗ for lightness, a∗ for red/green, b∗ for yellow/blue). These numerical systems provide an objective, device-independent way to describe and quantify colour, allowing for precise communication and comparison across different instruments and locations.This is the most widely used and versatile colour space. It's ideal for a broad range of applications in textiles, plastics, and coatings due to its uniform colour distribution, making it easy to define colour differences and set tolerances.

- Textiles: Used for matching dyed fabrics, evaluating colour fastness, and ensuring consistency across different batches and fibres.

- Plastics: Essential for controlling the colour of masterbatches, moulded parts, and ensuring colour consistency in end products.

- Coatings: Crucial for paint formulation, quality control of paints and varnishes, and assessing gloss and opacity.

While CIE L*a*b* provides a precise “address” for any colour in a standardized 3D space, it's often not enough to simply know the individual L*, a*, and b* values. What's truly critical in industrial applications is quantifying how much one colour differs from another. This is where Delta E (ΔE) comes in – it's the single, universally recognized metric for total colour difference.

CIE L*c*h*: A cylindrical transformation of L*a*b*, where ‘c' represents chroma(saturation) and ‘h' represents hue angle. This scale is often preferred for communicating colour in a more intuitive way, aligning with human perception of hue, saturation, and lightness.

Hunter Lab: Another three-dimensional colour space, similar to CIE L*a*b*, often used in various industries.

Yellowness Index (YI): A critical single-value metric for quantifying unwanted yellow discoloration in materials like plastics, textiles, and coatings. Measured by spectrophotometers using standards like ASTM E313, YI helps monitor degradation, ensure raw material purity, and maintain consistent product aesthetics. Essential for quality control and R&D.

Specialized Scales (e.g., Gardner, Iodine, Saybolt): While Lovibond® is a master in general colour measurement, they also offer instruments tailored to specific industry needs, using scales relevant to those applications (e.g., for transparent liquids like oils and chemicals).

What is Delta E and Why do we measure it?

- Objectivity: It provides an objective, numerical way to quantify colour differences, removing the subjectivity and variability of human visual assessment. What looks “close enough” to one person might be a significant mismatch to another

- Quality Control: Industries use ΔE to set strict tolerances for colour consistency in products like textiles, plastics, and coatings. If a production sample's ΔE from the target colour is within the acceptable limit, it passes; otherwise, it fails.

- Communication: ΔE provides a common, universal language for communicating colour requirements and deviations between suppliers, manufacturers, and clients.

- Troubleshooting: By seeing the individual ΔL*, Δa*, Δb* components, you can understand how a colour is off (e.g., too dark, too green, too yellow) and make targeted adjustments.

- Colour Fastness & Durability: It's used to track how much a colour changes over time due to exposure to light, heat, or chemicals, quantifying product degradation or stability.

- ΔE<1.0: Difference is usually not perceptible to the average human eye. Considered a “commercial match.”

- ΔE=1.0−2.0: Only perceptible by a trained eye or under close inspection. Often an acceptable difference in many industries.

- ΔE=2.0−3.5: A noticeable difference, but still acceptable for some applications.

- ΔE>3.5: Clearly perceptible colour difference; often considered a “mismatch.”

How to Choose the Right Colour Scale for Your Application: A Practical Guide

Choosing the optimal colour scale and instrument involves a systematic approach

- Opaque vs. Transparent: For opaque materials (most textiles, plastics, and coatings), reflectance measurements are key. For transparent liquids, transmission measurements are necessary.

- Surface Characteristics: Gloss, texture, and opacity can all influence perceived colour. Spectrophotometers with different measurement geometries (e.g., d/8° sphere for diffuse reflection, 45°/0° for directional reflection) are crucial for accounting for these factors.

- Always refer to the international (ASTM, ISO) and industry-specific standards relevant to your product and market. These often dictate the preferred colour space and measurement conditions.

- Spectrophotometers: These are the most comprehensive instruments, measuring the entire visible spectrum of light. They provide detailed colour data (e.g., spectral curves) and can calculate values in various colour spaces (L*a*b*, L*c*h*, etc.). Lovibond® offers a range of spectrophotometers, like the TR and TG Series for surface colour measurement.

By meticulously understanding the principles of colour, adhering to international standards, and strategically choosing the right colour scale and Lovibond® solution, businesses in the Textiles, Plastics, and Coatings industries can ensure impeccable colour quality, enhance brand reputation, and achieve significant operational efficiencies

Want to learn more about Lovibond® Spectrophotometers? Download brochure now!

Want to learn and understand more about colour? Join our online Course today for Free!

Please fill the details below and we will connect with you!

FAQ's

Why is accurate colour measurement so important in the Textiles, Plastics, and Coatings industries?

Accurate colour measurement is crucial for ensuring product consistency, maintaining brand identity, meeting precise customer specifications, optimising production efficiency, and reducing costly waste or reworks due to colour discrepancies.

What type of plastics can be measured using the Lovibond Spectrophotometer?

The Lovibond Spectrophotometer can measure a wide variety of plastic samples, including opaque, semi-transparent, and coloured plastics. It is suitable for pellets, sheets, moulded parts, and films, provided the surface is flat and clean.

How can colour consistency be maintained during production?

To maintain consistent colour:

- Use standard reference samples or master batches

- Measure colour at multiple production stages: raw material, in-process, and final product

- Define and monitor acceptable ΔE tolerance limits

- Ensure instrument calibration is done regularly

- Use automated colour measurement instruments like spectrophotometers instead of visual matching

What is Delta E (ΔE), and why do we measure it?

Delta E (ΔE) is a single numerical value that quantifies the total colour difference between two colours in the CIE L*a*b* space. We measure it to objectively assess how far a sample deviates from a target colour, set precise quality control tolerances, troubleshoot production issues, and communicate colour requirements clearly.

What is a "good" Delta E value?

A lower ΔE indicates a closer colour match. A ΔEab∗ value of less than 1.0 is generally considered an imperceptible difference to the average human eye, signifying an exceptionally precise colour match. However, “acceptable” ΔE values can vary by industry and application (e.g., ΔEab∗<2.0 or 3.0 might be acceptable for some commercial matches).

What corrective actions are taken when colour deviations occur?

If a batch is out of colour tolerance:

- Review pigment dosing and dispersion

- Check machine parameters (e.g., temp, mixing time)

- Inspect raw material consistency

- Re-measure after adjustments or remixing

Can Lovibond instruments measure all these different colour scales and parameters?

Yes, Lovibond offers a range of advanced spectrophotometers and colorimeters designed to measure various colour scales, including CIE L*a*b*, Delta E, and Yellowness Index, ensuring compliance with relevant international standards for Textiles, Plastics, and Coatings.

How does colour measurement help address the issue of metamerism?

Metamerism occurs when two colours appear to match under one light source but look different under another (e.g., fabric matching in daylight but not under fluorescent light). Spectrophotometers measure the full spectral curve of a colour, allowing them to analyse how a colour will behave under various illuminants. This enables formulators to create products that are less prone to metamerism, ensuring consistent colour appearance in different viewing environments.

How often should colour measurement instruments be calibrated, and why is it important?

Regular calibration is crucial for maintaining the accuracy and reliability of your colour measurement instruments. Lovibond instruments typically come with calibration standards (like white tiles) that should be measured daily or before critical measurements. Annual professional servicing and certification ensure your instrument continues to perform to factory specifications and industry standards.

Service Request

Service Request  Sales Enquiry

Sales Enquiry  Customer Reviews

Customer Reviews